Ramen recalled incidents have become increasingly prevalent in recent years, sparking concerns among consumers and industry stakeholders alike. The recall of ramen products, a staple in many households worldwide, raises significant questions about food safety, quality control, and regulatory compliance. As one of the most popular instant food items globally, ramen's recall has far-reaching implications that extend beyond mere consumer inconvenience.

From manufacturing defects to contamination risks, the reasons behind these recalls vary widely. However, each incident underscores the importance of stringent quality assurance processes and transparency in the food production chain. This article delves into the intricacies of ramen recalls, exploring their causes, impacts, and preventive measures to ensure consumer safety.

By understanding the factors contributing to ramen recalls and the actions taken by manufacturers and regulators, consumers can make informed decisions about their food choices. Additionally, this article aims to shed light on the broader implications of food recalls on the industry and public health, emphasizing the need for robust safety protocols.

Understanding Ramen Recalled: A Global Perspective

Overview of Ramen's Popularity and Market Presence

Ramen, a beloved dish originating from Japan, has transcended cultural boundaries to become a global phenomenon. Its versatility and convenience make it a staple in households across the world. According to Statista, the global instant noodle market was valued at approximately $46.6 billion in 2022, with ramen being one of the leading segments. This widespread popularity, however, also means that any issues affecting ramen production can have significant repercussions.

As demand for ramen continues to grow, so does the responsibility of manufacturers to ensure product safety. The ramen recalled incidents highlight the challenges faced by producers in maintaining quality and safety standards while catering to an ever-expanding market.

Common Reasons Behind Ramen Recalled

Manufacturing Defects

One of the primary reasons for ramen recalled is manufacturing defects. These defects can range from improper sealing of packaging to issues with cooking processes. A study published in the Journal of Food Science and Technology revealed that inadequate heat treatment during production can lead to the growth of harmful microorganisms, posing health risks to consumers.

Contamination Risks

Contamination is another major concern that leads to ramen recalled. Cross-contamination during production or storage can introduce harmful substances into the product. For instance, the presence of allergens such as peanuts or shellfish in non-allergenic ramen can pose severe health risks to sensitive individuals. Ensuring clean and controlled production environments is crucial in mitigating these risks.

Impact of Ramen Recalled on Consumers

Health Risks Associated with Recalls

The health implications of ramen recalled incidents are significant. Consuming contaminated or defective ramen can lead to foodborne illnesses, allergic reactions, and other health complications. According to the Centers for Disease Control and Prevention (CDC), foodborne illnesses affect millions of people globally each year, with many cases linked to improperly processed food products.

Economic Impact on Households

Beyond health concerns, ramen recalled incidents can also have economic implications for consumers. The cost of replacing recalled products, coupled with the inconvenience of finding suitable alternatives, can strain household budgets. Moreover, the loss of trust in certain brands can lead to a shift in consumer preferences, affecting market dynamics.

Industry Response to Ramen Recalled

Enhanced Quality Control Measures

In response to the rising number of ramen recalled incidents, manufacturers are implementing stricter quality control measures. Advanced technologies such as automated inspection systems and real-time monitoring are being adopted to detect and address issues early in the production process. These measures not only improve product safety but also enhance operational efficiency.

Regulatory Compliance and Standards

Regulatory bodies play a vital role in ensuring the safety of food products, including ramen. Compliance with international standards such as ISO 22000 and HACCP (Hazard Analysis and Critical Control Points) is essential for manufacturers. Regular audits and inspections by authorities help maintain high standards of food safety and quality.

Consumer Awareness and Education

Importance of Reading Labels

Consumers can play an active role in safeguarding their health by being more vigilant about the products they purchase. Reading labels and understanding ingredient lists can help identify potential allergens or contaminants. Additionally, staying informed about recall notices and updates from manufacturers and regulatory agencies is crucial in avoiding exposure to unsafe products.

Reporting Suspected Issues

In cases where consumers suspect a product may be defective or contaminated, reporting the issue to the appropriate authorities is essential. This not only helps in addressing the specific concern but also contributes to broader efforts in improving food safety standards. Many countries have dedicated platforms for consumers to report such incidents, ensuring prompt action by relevant stakeholders.

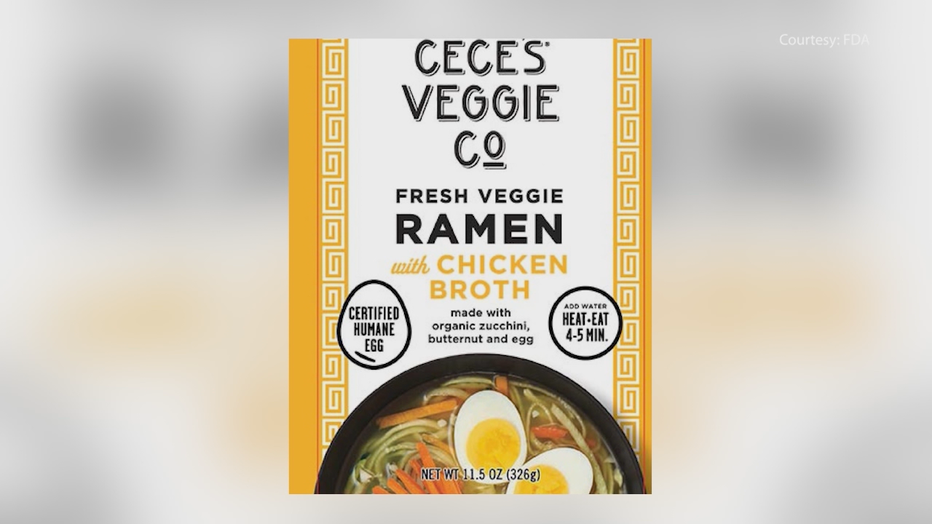

Case Studies: Notable Ramen Recalled Incidents

Incident 1: Packaging Defects

In 2021, a major ramen manufacturer issued a recall due to packaging defects that allowed air to enter the sealed packets. This compromise in packaging integrity led to the growth of mold in some batches, posing a health risk to consumers. The company responded swiftly by issuing a public apology and offering refunds to affected customers, while also implementing enhanced packaging technologies to prevent future occurrences.

Incident 2: Allergen Contamination

Another notable incident involved the contamination of a popular ramen brand with undeclared allergens. The presence of peanuts in a product labeled as peanut-free led to a widespread recall. This incident highlighted the importance of accurate labeling and strict adherence to allergen management protocols in food production.

Preventive Measures and Best Practices

Implementing Robust Quality Assurance Protocols

To minimize the risk of ramen recalled incidents, manufacturers must adopt comprehensive quality assurance protocols. Regular training of staff, investment in advanced technologies, and adherence to industry standards are key components of an effective quality assurance program. Collaboration with regulatory bodies and participation in industry initiatives can further enhance safety measures.

Engaging in Transparent Communication

Transparent communication with consumers and stakeholders is vital in managing the impact of ramen recalled incidents. Prompt notification of recalls, clear instructions for affected products, and proactive engagement with customers can help restore trust and confidence in the brand. Manufacturers should also leverage digital platforms to disseminate information effectively.

Future Outlook: Innovations in Food Safety

Emerging Technologies in Food Production

The food industry is witnessing rapid advancements in technology aimed at enhancing safety and quality. Innovations such as blockchain for traceability, artificial intelligence for predictive analytics, and nanotechnology for packaging are revolutionizing food production processes. These technologies offer promising solutions to address the challenges associated with ramen recalled incidents.

Global Collaboration for Enhanced Safety Standards

Addressing food safety concerns requires global collaboration among manufacturers, regulatory bodies, and research institutions. Sharing best practices, developing standardized protocols, and fostering knowledge exchange can lead to the establishment of more effective safety measures. Such efforts can ensure that incidents like ramen recalled become increasingly rare in the future.

Conclusion

Ramen recalled incidents highlight the critical importance of food safety and quality assurance in the global food industry. By understanding the causes and impacts of these recalls, manufacturers and consumers alike can take proactive steps to mitigate risks and ensure product safety. Implementing robust quality control measures, adhering to regulatory standards, and fostering transparent communication are key to addressing the challenges posed by ramen recalled incidents.

We invite you to share your thoughts and experiences regarding ramen recalled incidents in the comments section below. Your feedback is invaluable in shaping future discussions and initiatives in food safety. Additionally, feel free to explore other articles on our site for more insights into the world of food and nutrition.

Table of Contents

- Understanding Ramen Recalled: A Global Perspective

- Common Reasons Behind Ramen Recalled

- Impact of Ramen Recalled on Consumers

- Industry Response to Ramen Recalled

- Consumer Awareness and Education

- Case Studies: Notable Ramen Recalled Incidents

- Preventive Measures and Best Practices

- Future Outlook: Innovations in Food Safety

- Conclusion